Turning Services

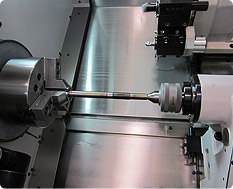

With numerous, high profile customers in an array of industries, JB Tool, Die & Engineering, Inc. leads the way in turning services. With a fast response and turnaround time, we provide turning services suited for a wide host of applications.

We specialize in working within extremely tight tolerances. Part diameters and lengths can vary depending on the lathe used. Machining processes available to our customers are numerous, and materials we work on, from standard to precious and exotic metals, plastic polymers, and more, are practically limitless. Our top-of-the-line, 2-axis lathes include center, CNC, gap bed, and tracer lathes. We also manufacture various types of fixturing. Our huge range of secondary services further enhances our level of quality and convenience.

With emergency and rush services available and short lead times, customers find our turning services to be superior. We can handle any size job, and take pride in our quality, expertise, and commitment to the client. Please contact us with any questions, and see below for details.

Capabilities

| Industry Focus | Aerospace Agricultural Automotive Electric Motors Electronic Energy Food Processing Industrial Machine Tool | Marine Medical Military Optical Packaging Pharmaceutical Plastics Metal Stamping Wire |

| Intended Applications | Machine components Engine components Turbine components Hydraulic components Construction equipment Shafts Castings Forgings Valves | Spindles Bushings Cams Dies Tooling Fixtures Gauges Molds |

| Tolerances | Straightness : ± 0.0005 Concentricity: ± 0.0002 | Diameter (outer/inner): ± 0.0002in Length (over in): ± 0.0005 in |

| Part Diameter - CNC | Max Though Spindle 3.5in | Max Chucking 12in |

| Part Diameter - Engine Lathe | Max Though Spindle 3in Max Chucking 48in | Max Turn Dia. 52in |

| Part Length Between Centers - CNC | Max 40in | |

| Part Length Between Centers - Engine Lathe | Max 144in | |

| Machining Processes | Broaching Spline Parting/Cutting Facing Turning:

Threading

Internal Forming | Knurling Boring Drilling Counterboring Countersinking Pocketing Profiling Reaming Tapping Thread Milling Hard Turning Thin Wall Turning OD Grinding |

| Materials (Metals) | Alloy Steels Aluminum Brass Bronze Alloys Carbon Steel Copper Iron Lead | Magnesium Monel Nickel Powdered Metals Stainless Steel Titanium Tool Steels Tungsten |

| Materials (Exotic & Precious Metals) | Inconel Invar Kovars | Monel Superalloys Tantalum |

| Materials (Plastic Polymers) | ABS (Acrylonitrile Butadiene Styrene) Acetal Acrylic Fiberglass Reinforced Plastics Nylon Phenolic Polyamide-Imide Polycarbonate Polyetheretherketone (PEEK) Polyetherimide | Polyethylene Polyphenylene Sulfide Polypropylene Polystyrene Polysulfone PTFE (PolyTetraFluoroEthylene) PVC (Polyvinyl Chloride) PVDF (Polyvinylidene Fluoride) Teflon |

| Materials (Other Materials) | Ceramic Composite Materials | Fiberglass Graphite |

| Equipment | Lathes

|

|

| Fixturing | Collet Three-jaw chuck | Four-jaw chuck In-House Fixturing & Tooling |

| Equipment Capabilities | CNC Control Capabilities Large Swing Lathe | Bar Feed CAM Programming |

| Machinery Axis | 2 | |

| Secondary Services Offered | Assembly Drilling Deep hole Drilling Tapping Bending Threading Broaching Counter Sinking Pressing Milling Reaming | Welding Plating Passivating Etch and Chromating Heat Treating Grinding Anodizing Inserting Plastic Molding EDM Certification |

| Industry Focus | Aerospace Agricultural Automotive Electric Motors Electronic Energy Food Processing Industrial Machine Tool | Marine Medical Military Optical Packaging Pharmaceutical Plastics Metal Stamping Wire |

| Advantages of Turning | Tight tolerances Short lead times |

|

| Production Volume | Specialty Production Shop Prototype Low Volume | Small Run Large Run |

| Lead Times Available | Quoted on job by job basis Emergency services available | Rush Services Available |

| Industry Standards | ISO 9001-2008 REGISTERED | |

| File Formats | AutoCAD (DWG) BMP Bit Mapped Graphics Catia (CGR) DXF Drawing Interchange Format, or Drawing Exchange Format GIF Graphics Interchange Format IGES Initial Graphics Exchange Specification, ANSI file format. Inventor (IDW, IPT) | JPG or JEPG Joint Photographic Experts Group MasterCam (MDX, MC8, MC9, SET) Portable Document Format SolidWorks (SLDPRT,SLDDRW,SLDDRT) STEP Standard for the Exchange of Product Model Data TIFF Tagged Image File Format |

Portfolio

- Structural Steel Fabrication of Stator Support Assembly Ring

- Custom Fabrication for the Aerospace Industry

- Gas Turbine Component Fabrication

- On-Site Service Relocation of Manufacturing Facility Equipment

- Custom Manufacture of Rotary Cap Slitting Machine

- Custom CNC Milling of Tool Steel

- Molded Tool Steel Cavity

- Precision Machine Design of a Rotor Core Assembly Machine