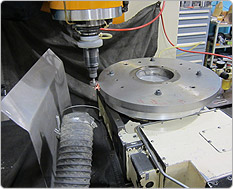

Mechanical Steel Fabrication of Radial Plate & Axial Cams

JB Tool, Die & Engineering, Inc. engineering department worked with a client from the high speed manufacturing industry to design cams for their equipment. Using the customer supplied part, we began the fabrication process with reverse engineering to produce a 2d drawing, CNC machining the 8620 steel to a thickness of 1 ½”, and then grinding the cams to the specific requirements. For this client we produced radial or plate cams and axial cams (face and cylindrical or barrel). On this fabrication project, we worked to tolerances as tight as ±.001″.

Contact JB Tool & Die today to learn more about our mechanical steel fabrication services. The following table outlines the details of this cam fabrication project.

Mechanical Steel Fabrication Project Highlights

| Capabilities Applied/Processes (Machining, Molding, Welding, etc...) | Engineering Turning | Machining CNC Grinding |

| Tightest Tolerance | +/- .001" | |

| Material Type | ASTM 8620 | |

| Material Thickness | 1 ½" | |

| Industry for Use | High Speed Manufacturing | |

| Standards Met (Customer Supplied Print, ISO, ASTM, etc...) | Customer Supplied Print | |

| Product Name | Cam for high speed manufacturing | |

| Types of Cams manufactured: | Radial or Plate Cams and Axial Cams (face and cylindrical or barrel) |

|