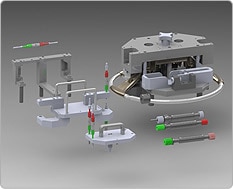

Gage Design and Manufacture

We were approached by an automotive OEM to design and build gages for use in production process capability verification. Beginning with CAD modeling to design the gages, we manufactured the components of the gages using our CNC turning and machining equipment from A2 tool steel, aluminum, machine steels, and carbide. We applied black oxide and titanium nitride coatings to protect the components from wear and provided each of these go/no-go and attribute gages with Certificates of Conformance (COC). Manufactured to tolerances of ±.0002″, we met ANSI, H28 Reference, and NIST standards.

JB Tool & Die has been on the cutting edge of design and technology for over 50 years. To inquire about this gage design and manufacture project or products designed and tailored to your requirements, please contact us today.

Gage Design and Manufacturing Project Highlights

| Capabilities Applied/Processes (Machining, Molding, Welding, etc...) | Engineering Turning | Machining Inspection and testing where applicable |

| Tightest Tolerance | +/- .0002" |

|

| Material Types | Machine Steels, A2 Tool Steel, Aluminum, Carbide |

|

| Material Finish (Paint, Plating, Powder Coating, etc...) | Black Oxide, Titanium Nitride |

|

| Secondary Operations Applied | Certificate of Conformance provided with each gage |

|

| Industry for Use | Automotive | |

| Standards Met (Customer Supplied Print, ISO, ASTM, etc...) | ANSI, H28 Reference, NIST | |

| Project Scope | Design and manufacture gages for use in production process capability verification |

|

| Design Work (CAD Modeling, FEA, etc.) | CAD Modeling |

|

| Product Description | Go/No-Go and Attribute Gauging for in process verification |

|