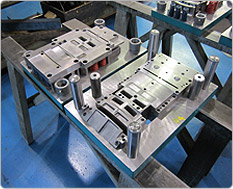

Progressive Stamping Die Fabrication for Automotive OEM

In need of a progressive stamping die, an automotive OEM turned to JB Tool, Die & Engineering, Inc. to take advantage of our experience in die and tool making. Working with the customer supplied specifications, our team designed the die and machined the details from A2 and D2 tool steels. This project required us to use wire and sinker EDM technology to create the intricate details of the die. After machining, the die was polished, inspected for flaws, and tested to ensure that it performed at the highest level. As always, our goal is perfection and we worked within tolerances of ±.0002″ throughout the manufacturing of this project.

We have the skills, tools, and ability to ensure that our die division can produce any die you need, no matter how complicated. Please contact us today to learn more about our die making services and see the table below for details on this progressive stamping die fabrication project.

Progressive Stamping Die for the Automotive Industry Project Highlights

| Capabilities Applied/Processes (Machining, Molding, Welding, etc.) | Engineering Machining | Wire and Sinker EDM Polishing and Inspection |

| Tightest Tolerance | +/- .0002" | |

| Material Type | Machine Steels, A2 and D2 Tool Steels | |

| Secondary Operations Applied | Product Verification through Die Testing | |

| Industry for Use | Automotive | |

| Standards Met (Customer Supplied Print, ISO, ASTM, etc...) | ANSI, Customer Specifications | |

| Product Name | Progressive Stamping Die | |

| Project Scope | Design and manufacture progressive stamping die | |

| Design Work (CAD Modeling, FEA, etc..) | CAD Modeling, FEA | |