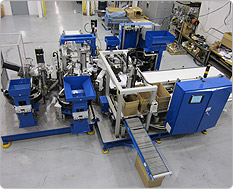

Assembly Machine Fabrication for the Power Generation Industry

We were approached by a customer working in the power generation industry to design a machine that would assemble and package power rectifier components. Our engineers worked closely with the client to design a system that would meet their needs. With their input we completed a machine that would attach the rectifier components to create the base, test for continuity and voltage, and laser etch the assembly, and then package the components for shipping. Final machining and controls integration were done in-house by our expert staff.

JB Tool & Die has over 50 years experience in machining and tool making. Contact us to learn more about this assembly machine fabrication project or see the table below for more details.

Assembly Machine Fabrication Project Highlights

| Capabilities Applied/Processes (Machining, Molding, Welding, etc...) | Engineering Machining | Controls Programming and Testing |

| Industry for Use | Power Generation | |

| Standards Met (Customer Supplied Print, ISO, ASTM, etc...) | Customer Specifications | |

| Product Name | Power Rectifier Assembly & Packaging Machine | |

| Project Scope | Concept Design to automate assembly of power rectifier components and then package assemblies for shipment. |

|

| Design Work (CAD Modeling, FEA, etc.) | CAD Modeling, FEA | |

| Project Description |

|

|